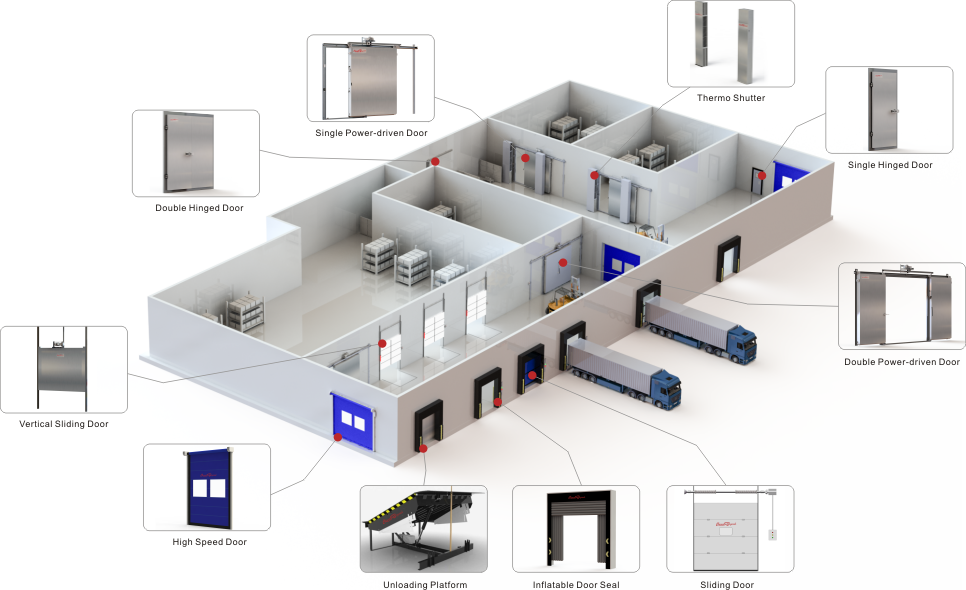

Cold Storage Loading Dock Solution

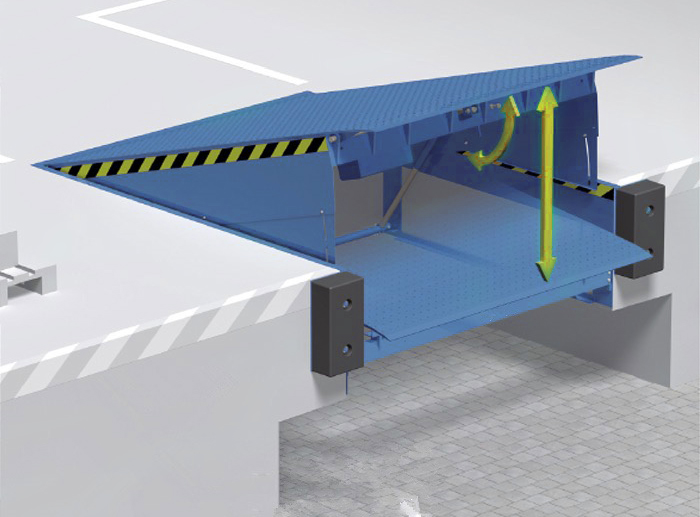

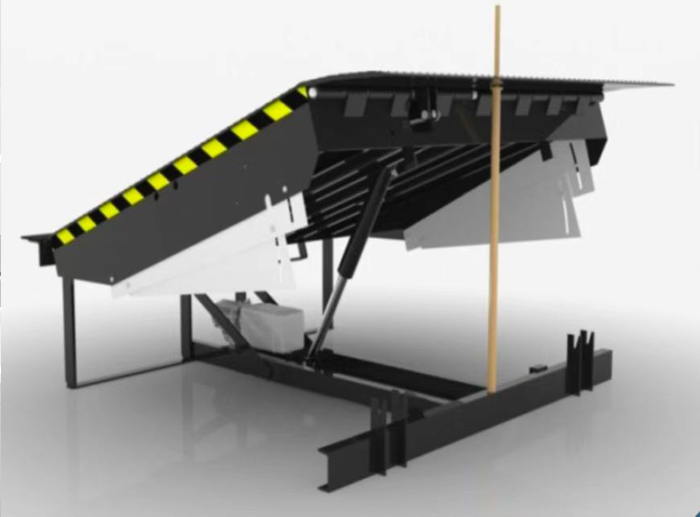

Cold storage loading dock solution includes 3 parts: sectional lifting insulation door, inflatable door seal and hydraulic loading ramp.

Modern cold chain logistics centers or food factories have increasingly high requirements for the cleanness, temperature control and the thermal insulation during loading/unloading. The loading/unloading platform is installed outside the warehouse.The top and sides of the doorframe are equipped with inflatable seals to seal the freight car during loading and unloading, protecting the goods and improving the internal environment of the warehouse. The retractable loading platform ensures docking between the carriage and the platform ground.

Sectional Lifting Insulation Door

With sealing from top, sides and bottom, Sectional lifting insulation doors excel at minimizing the air flow and condensed water in the workplace, resulting in an optimal working conditions and energy consumption.With sealing from top, sides and bottom, Sectional lifting insulation doors excel at minimizing the air flow and condensed water in the workplace, resulting in an optimal working conditions and energy consumption.

The thermal insulation PU door panel with a thickness of 67 mm has excellent thermal insulation performance, and the thermal insulation coefficient can reach 0.51 W/(m2·K)*. Padding between the double steel door panels can effectively reduce the formation of condensed water inside the door panels which can reduce the heat loss. It is an ideal choice for food and cold chain logistics industry.

Inflatable Door Seal

Inflatable door seals are suitable for trucks with different sizes. It has a wide range of adjustment to ensure good sealing and prevent the convection between the cold air and hot air realizing energy saving.The inflatable door seal tightly surrounds the truck compartment without affecting the opening of the vehicle doors. Turn off the blower after loading and unloading, the airbag will rapidly discharge the gas in the airbag under the action of counterweight and built-in tensioning rope.

Frame Structure: The top and side guard plates are made of double-layer thermal insulation steel plates with a thickness of 42 mm, available to all the color .

Corner Material: anodized aluminum alloy profile.

Curtain Plate and Fiber: The top and side curtain plates are 3 mm thick. Both sides are made of UPVC-coated double-layer polyfabric fibers to protect the inflatable bladder. The inflatable airbag made by high-frequency welding can resist harsh weather and maintain elasticity for a long time.

Air Blower: A powerful blower continuously inflates the air bag during the whole process of loading and unloading to ensure continuous good sealing. A small vent under the air race keeps the bag at constant pressure and blows away the water droplets attached to the transport vehicle.

Sealed Corner Pads: standardized foam-filled sealed corner pads.

The standard length of the telescopic lip plate is 500mm,extended length of 1000mm or 1200mm is available.For transport vehicles of different types and widths,we can also choose three-section lip plate to match.Its two sides of the lip plate width of about 170mm,which can easily adapt to various vehicle.

Application

For more information, please contact