ABP Slurry Ice Unit

Slurry Ice

Slurry ice is a fluid consisting a mixture of brine and spherical ice crystals, made of millions of ice "micro-crystals" (typically 200 to 500 micron in diameter), the mixture of brine and spherical ice crystals has very good flow properties, making them easy to distribute through conventional pumps and piping and over product in direct contact chilling applications.

Slurry ice is well known for its advantages of rapid chilling, pumpable ice crystals and low energy consumption, it is commonly used in a wide range of applications such as air conditioning, packaging, industrial cooling processes, supermarkets, and cooling /storage of fish, poultry and other perishable products.

Advantages of Slurry Ice System

● High efficiency: ice generator can produce fine slurry ice efficiently.

● Modular unit: allows group duplication of system and reliable operation.

● No need to handle additional refrigeration installation on site, plug and play can save labor cost.

● All the pipe line can be prepared as kit in factory and make easy connection on site, or the whole system is containerized.

● 100% ecological material of brine or sea water is used.

● ABP owned design of control system with touch screen interface, the control software integrates parameters for different applications.

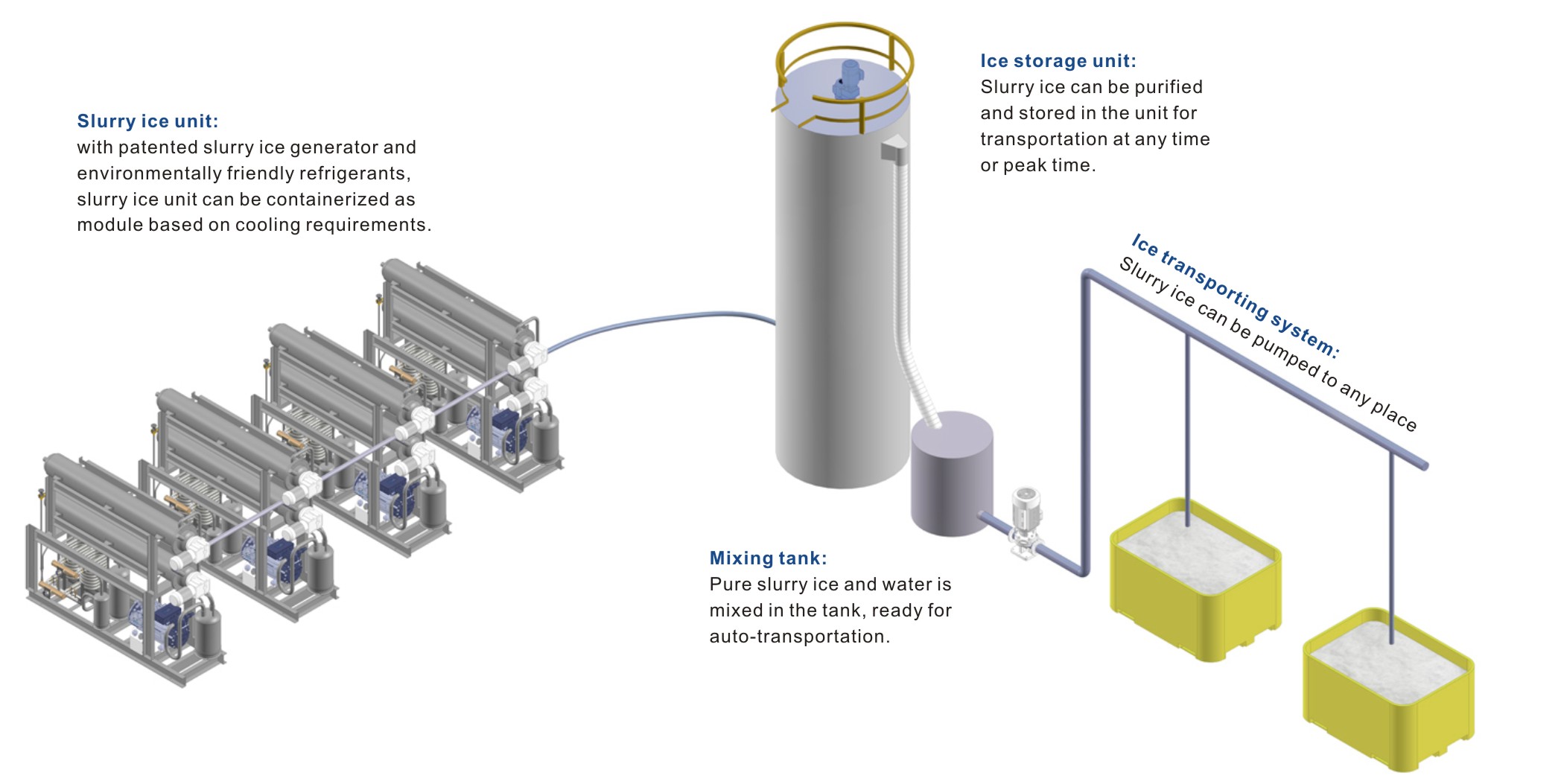

Slurry Ice System Diagram and Products

Slurry Ice Unit

? Capacity: 40KW (10ton/d ice crystals equivalent)

? Dimensions: LxWxH 2400x716x1780

? Water-cooled double pipe condenser

? Modular unit design is suitable for on-land and on-board applications

? Thermal expansion valve of refrigeration control

? For the selection of different model, please contact our sales person below.

-

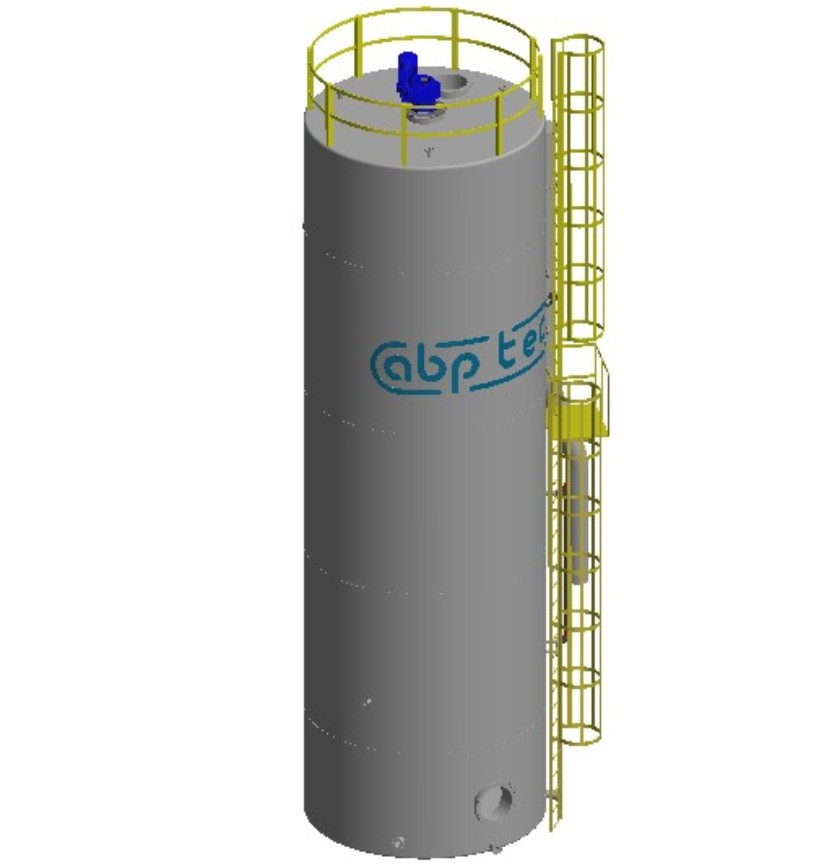

Vertical-type Mixing Tank

? FRP tank (SS316 material can be optional) with SS316 blender

? Suitable for 30% ice concentration slurry

? Effective volume 1.0~10.0m3

? Ice slurry can be suitable for standard centrifugal pump

? Sensors integrated

? For the selection of different model, please contact our sales person below.

-

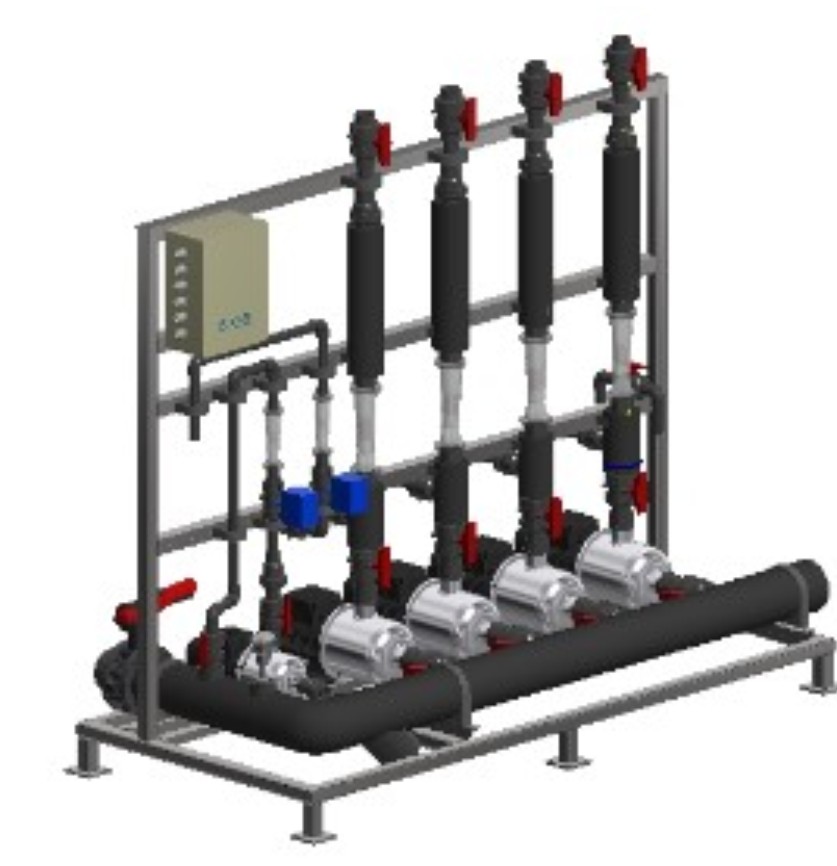

Pump Station

Pump Stations

? Factory-built pump station for ice slurry circulation with groups of unit SIGF-100H

? Integrated sensors and motorized valves

? Material SS316 for circulation pumps

? UPVC pipes and fittings are connected to have inlets and outlets ready for on-site connection

? For the selection of different model, please contact our sales person below.

-

? Food grade resin FRP with polyurethane insulation

? Effective storage of ice crystals from 10~50 tons depending on model size

? Output of ice crystals from 5~10ton/h depending on model size

? Gear motor of heavy duty

? Integrated sensors and Saving space

? For the selection of different model, please contact our sales person below.

References

Seafood Processing

In the food factory, products usually need to be chilled and preserved during processing.

Ice slurry and its crystals are produced and stored in the storage (ICSS).

Depending on requirements, ice crystal can be mixed with different kinds of ice concentration and pumped to the designated location.

Brief of The System

|

Slurry Unit Model |

SIGF-070H x 8 |

|

Mixing Tanks |

ICMS-2000V x 1 |

|

Pump Station |

PS-324 x 1 |

|

ICSS Storage |

ICSS-28-90 x 1 |

|

Ice Concentration |

30% |

|

Yield of Slurry Ice |

60tons/d |

Chemical Industry

In the chemical factory, the waste water is usually the salt solution which can be used to produce slurry ice and ice crystals stored in storage (ICSS).

The crystals can be used in chemical process to absorb reaction heat.

Producing ice crystals from waste water can reduce the capacity of waste water handle system (MRV) and the factory facility investment

Brief of The System

|

Slurry Unit Model |

SIGF-400H x 2 |

|

ICSS Storage |

ICSS-36-120 x 1 |

|

Ice Concentration |

100% (crystals) |

|

Yield of Slurry Ice |

50 ton/d |

For more information, please contact