Antarctic Krill Fishing Vessels

As one of the largest biomass in the world and famous for its high content of protein, Antarctic krill is becoming more and more attention. Since 2008, Chonson Beyond started studied the characteristics of krill and krill processing, summarizing the best on-board krill processing solutions. Based on requirements from shipowners, final products can be human-grade krill meal, feed grade krill meal, aqua-grade krill oil, whole round krill and krill meat.

-

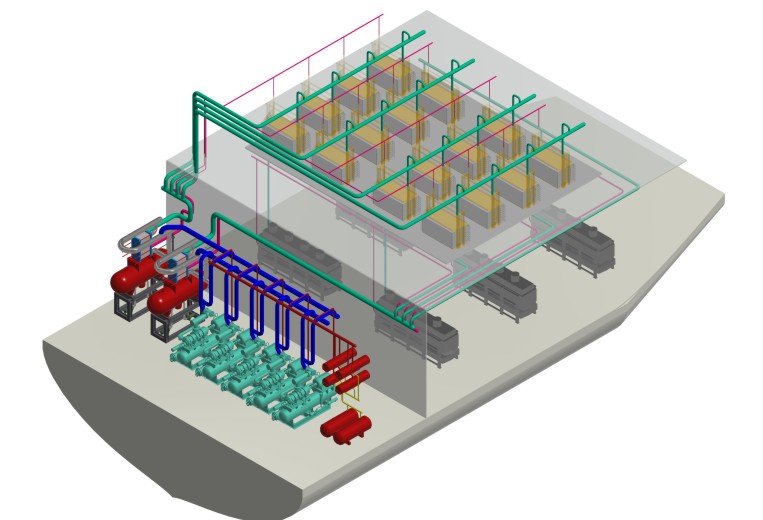

Features and Parameters of Refrigeration System:

● Compressor:screw compressor from Japanese MYCOM ;● Auxiliary equipment (pressure vessel): from domestic top brands;● Blast-freezing: horizontal plate freezers with efficient heat transfer;● Air blower: made of stainless steel + hot-dip galvanized zinc preventing corrosion;● Refrigeration pipes: made of special material for low temperature;● Air supply grating: made of aluminum alloy based on Japanese mould, with load of up to 10t/㎡, suitable for forklifts;● Refrigerant: R404A/R507A/R717, secondary heat exchanging with Calcium chloride salineLeakage prevention: only does seawater circulate between engine room and cabin;● There is no safety hazard or damage to the cargo;● Pre-assembly: assembly of pipes and cables in the factory, reducing on-site workload;● Unit structure: with a compact structure, the unit is space-saving and easy maintenance.

-

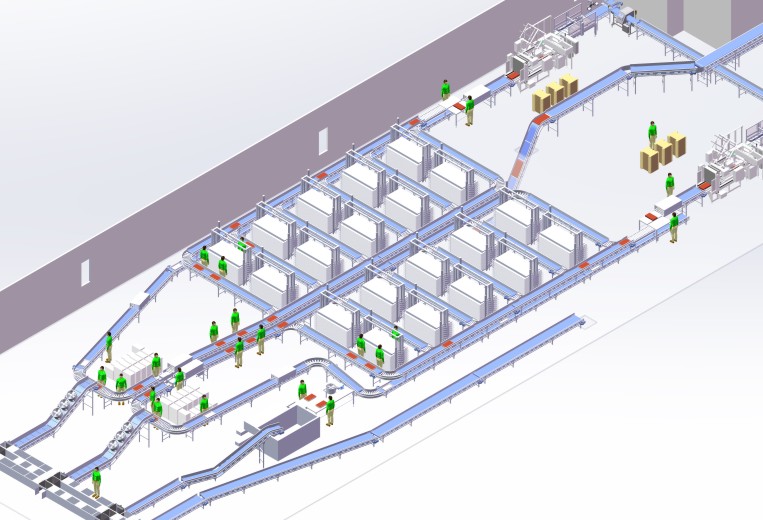

Features and Parameters of Krill Processing Line Solution( krill washing, conveying, weighing, freezing and packaging):

● Optimized processing equipment: special design according to krill characteristics;

● Process flow: a reasonable process flow is set based on years of practical experience and fishing protocol of vessel owners;

● Flexible change: the arrangement of process and personnel can be flexibly changed based on different final product;

● Krill buffer: material can be distributed in an easy and energy-saving way;

● Krill conveyor: the motor, bearing and belt of conveyor are imported from foreign countries and assembled in China, increasing the competitiveness;

● Krill packaging: the automatic packaging equipment is from the top brand with reliable and efficient operation;

● Processing management: the processing system can be managed based different areas, realizing interlocking start-stop;

● Material: equipment are made of stainless steel,meeting the requirements of food production.

-

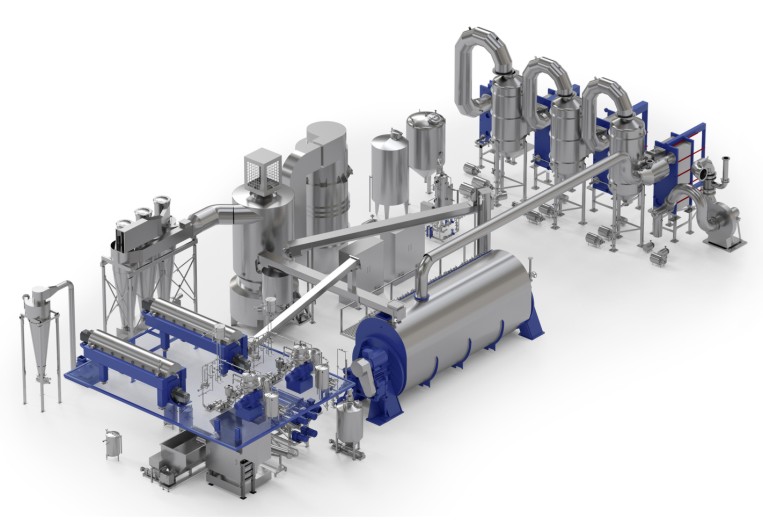

● Competitive design*assembly: krill wet line is from Alfa Laval; krill hot line is from Osgard;

● Auxiliary equipment is from reliable domestic brands;

● Material: made of 316L stainless steel;

● Technical support: offered by Alfa Laval;

● Automatic processing: high automation, reducing the labor;

● Key part of processing line: centrifugal separator and plate evaporator;

● CIP cleansing: making sure a healthy operation;

● Excellent final product:

※ Pure fat without oxidation;

※ Almost 100% nutrient from raw material is kept in krill meal;

※ Compared with conventional way, water can be saved up to 35%;

● MSC certificated processing: discharge from board is closed to pure water.

Reference 1

Krill Fishing Vessel

Vessel owner: Liaoning Pelagic Fishing Company

Vessel name: FU XING HAI

Length: 136.60m

Breadth: 24.00m

Draught: 7.60m

Main engine: 9000.00kw

Processing capacity: krill meal 110t/day.

Reference 2

Krill Fishing Vessel

Vessel owner: Ningbo Pelagic Fishing Company

Vessel name: YONG LI

Length: 140m

Breadth: 24.00m

Processing capacity: krill meal 110t/day.

For more information, please contact